A Method of 3D Printing which is Consistent with Natural Direction in Shape

Kanada, Y., International SFF Symposium 2013, August 2013.

[ 日本語のページ ]

[ Poster content + explanation ]

[ Updated poster PDF file ]

[ Poster photo ]

Abstract: Usually, objects are horizontally sliced when printed by 3D printers. Therefore, if an object to be printed, such as a collection of fibers, originally have natural direction in shape, the printed direction contradicts with the natural direction. By using proper tools, such as field-oriented 3D paint software, field-oriented solid modelers, field-based slicing algorithms, and non-horizontal FDM 3D printers, the natural direction can be modeled and objects can be printed in a direction that is consistent with the natural direction. This consistence results in embodiment of momentum or force in expressions of the printed object. To achieve this goal, several manufacturing problems, but not all, have been solved. An application of this method is (Japanese) 3D calligraphy.

Abstract: Usually, objects are horizontally sliced when printed by 3D printers. Therefore, if an object to be printed, such as a collection of fibers, originally have natural direction in shape, the printed direction contradicts with the natural direction. By using proper tools, such as field-oriented 3D paint software, field-oriented solid modelers, field-based slicing algorithms, and non-horizontal FDM 3D printers, the natural direction can be modeled and objects can be printed in a direction that is consistent with the natural direction. This consistence results in embodiment of momentum or force in expressions of the printed object. To achieve this goal, several manufacturing problems, but not all, have been solved. An application of this method is (Japanese) 3D calligraphy.

An online-journal version is available.

Introduction to this research theme: 3D shape formation technologies

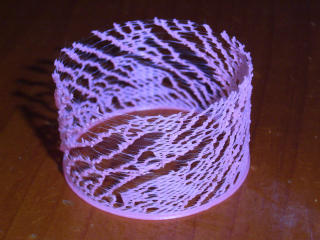

Abstract: 3D printing technology usually aims reproducing objects deterministically designed by 3D CAD tools. However, 3D printing can generate patterns similar to randomized (non-deterministic) 1D or 2D cellular automata (CA). Cheap fused deposition modeling (FDM) 3D printers can be used for this purpose. By using an FDM 3D printer, melted plastic filament is extruded by a hot nozzle to shape a 3D object. They can generate CA-like patterns with constant head motion and constant filament extrusion and with unintended fluctuation but no explicit randomness. Because of fluctuation, every time the printer generates a different emergent pattern. This paper proposes a method for printing seaweed-like patterns of 1D and 2D CA using FDM, and computational CA models. This method will open a new horizon of 3D printing applications.

Abstract: 3D printing technology usually aims reproducing objects deterministically designed by 3D CAD tools. However, 3D printing can generate patterns similar to randomized (non-deterministic) 1D or 2D cellular automata (CA). Cheap fused deposition modeling (FDM) 3D printers can be used for this purpose. By using an FDM 3D printer, melted plastic filament is extruded by a hot nozzle to shape a 3D object. They can generate CA-like patterns with constant head motion and constant filament extrusion and with unintended fluctuation but no explicit randomness. Because of fluctuation, every time the printer generates a different emergent pattern. This paper proposes a method for printing seaweed-like patterns of 1D and 2D CA using FDM, and computational CA models. This method will open a new horizon of 3D printing applications.

Abstract: When creating forms by using a 3D printer, usually, a static (declarative) model designed by using a 3D CAD system is translated and sent to the printer. However, widely-used FDM-type 3D printers inputs a dynamical (procedural) program that describes control of motions of the print head and extrusion of the filament. If the program is expressed by a programming language or a library in a straight manner, 3D objects can be created by a method similar to turtle graphics. Such a library, “turtle 3D printing” library, which is open-source, was described by Python and used (tried). Although this problem has a problem that it cannot print in the air; however, if this problem is solved by an appropriate method, shapes drawn by 3D turtle graphics can be embodied by this method.

Abstract: When creating forms by using a 3D printer, usually, a static (declarative) model designed by using a 3D CAD system is translated and sent to the printer. However, widely-used FDM-type 3D printers inputs a dynamical (procedural) program that describes control of motions of the print head and extrusion of the filament. If the program is expressed by a programming language or a library in a straight manner, 3D objects can be created by a method similar to turtle graphics. Such a library, “turtle 3D printing” library, which is open-source, was described by Python and used (tried). Although this problem has a problem that it cannot print in the air; however, if this problem is solved by an appropriate method, shapes drawn by 3D turtle graphics can be embodied by this method.

Abstract: Material is stacked vertically and layer-by-layer in conventional additive manufacturing (AM) methods. An object with overhang or skewed stacking structure, such as a plain dish or an empty sphere, is difficult to be created by these methods without support material. This paper proposes a layer-less fused-deposition-modeling (FDM) method that enables mostly horizontal stacking of filament without support material. Such filament-stacking is enabled by increasing the height of the print head gradually, i.e., without layer transitions that make horizontal stacking difficult. The proposed method also allows controlling printing directions and various printing-direction-dependent expressions, such as fiber-like textures or brilliance, which make AM products attractive as final products for consumers or as some kinds of industrial products. Objects to be printed can be modeled as directed solid models designed by a component-based method (i.e., a new CAD based method) or a generative method, which are completely different from conventional CAD based methods.

Abstract: Material is stacked vertically and layer-by-layer in conventional additive manufacturing (AM) methods. An object with overhang or skewed stacking structure, such as a plain dish or an empty sphere, is difficult to be created by these methods without support material. This paper proposes a layer-less fused-deposition-modeling (FDM) method that enables mostly horizontal stacking of filament without support material. Such filament-stacking is enabled by increasing the height of the print head gradually, i.e., without layer transitions that make horizontal stacking difficult. The proposed method also allows controlling printing directions and various printing-direction-dependent expressions, such as fiber-like textures or brilliance, which make AM products attractive as final products for consumers or as some kinds of industrial products. Objects to be printed can be modeled as directed solid models designed by a component-based method (i.e., a new CAD based method) or a generative method, which are completely different from conventional CAD based methods.